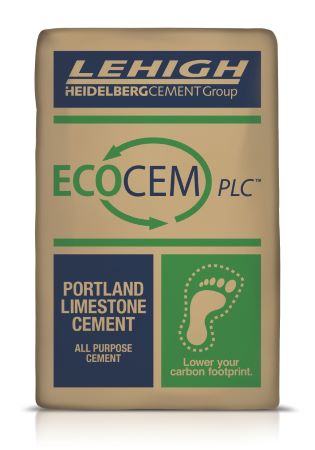

Lehigh Hanson is pleased to announce the release of its new bag design for Lehigh Cement’s EcoCemPLCTM, the greener alternative to ordinary portland cement that lowers the carbon footprint of a project while delivering the performance and strength customers expect from Lehigh Cement.

The redesign comes as part of Lehigh Hanson’s ongoing commitment to reducing its carbon footprint and offering more sustainable options for its cement products which are typically used in mortars, grout, precast and ready mixed concrete, paving applications, soil stabilization and concrete blocks and pavers.

“The new bag design and transition to EcoCemPLCTM is about more than aesthetics — it’s about clearly communicating the proven benefits of EcoCemPLCTM to sustainably minded customers,” said Alex Car, president of Lehigh Hanson’s Northeast Region.

Features of the refreshed packaging design for EcoCemPLCTM include the “reduced carbon footprint” icon, featured prominently in the new bag design to emphasize EcoCemPLCTM’s demonstrated carbon-reduction benefit: about a 10% reduction in CO2 emissions vs. ordinary portland cement.

The product is also now easily identifiable as a portland limestone cement, which contains about 10% more limestone content than ordinary Type I & II portland cement. EcoCemPLCTM can be employed for full-scale residential and commercial applications as an Earth-friendly cement option that doesn’t compromise consistency, versatility and performance.

The newly designed EcoCemPLCTM bag will hit big-box stores and dealers in October. For more information on EcoCemPLCTM, visit www.lehighhanson.com/products/cement/EcoCemPLC.