Tips and guidance

In addition to specifying Heidelberg Materials' cement for your next project, below are some tips, job site reminders and helpful links to ensure satisfaction with your masonry project.

Mixing Instructions

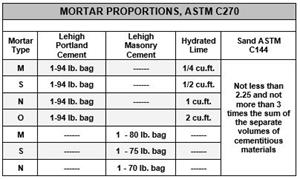

MASONRY AND PORTLAND & LIME BLENDS:

Each bag of Lehigh Masonry or Portland & Lime Blended Cement should be mixed with the appropriate volume of sand and water, as per ASTM C270. Place approximately one-half the estimated amount of water

into the mixer, followed by one-half of the sand, and all of the cement. Add balance of sand and gradually add remaining water to obtain the desired working consistency. Mix all material 5 minutes in a mechanical mixer.

PORTLAND CEMENT:

Proportion and mix according to project specifications.

COMPRESSIVE STRENGTH TESTING:

ASTM C270 is a laboratory specification utilizing a prescribed volume of water to evaluate the compressive strength of mortars. ASTM C780 is a field specification and should be utilized to evaluate mortars mixed in the

field. Compressive strength results of field mortars utilizing ASTM C780 cannot be compared to the listed minimum compressive strength values given in Table 1 of ASTM C270.

Walls should be cleaned with a mild detergent or proprietary cleaner. Cleaning materials shall be in accordance with the manufacturer’s recommen¬dations. Test all cleaning materials on a sample panel before use. Do not clean colored mortar joints with acid as it will loosen pigments and expose sand grains. Sample panels require 7 to 21 days for complete hydration to occur depending on weather and site conditions. Do not clean panel for a minimum of 7 days after construction.